Site Search

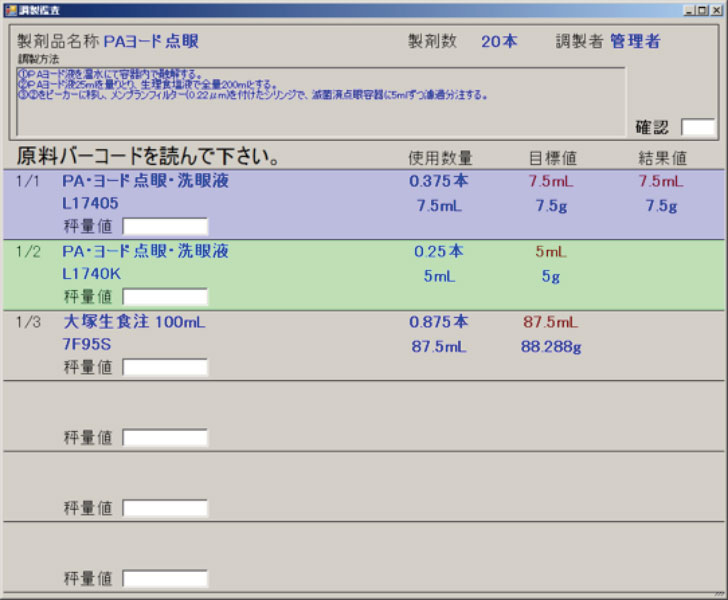

When a registered recipe is selected, the ingredients and quantities to be used, the target weights, etc., are automatically displayed.

An image of the finished product can also be displayed, preventing production errors.

Strict inspections are carried out at each step of the process, from preliminary inspection, preparation inspection, and verification of testing prescribed by the Japanese Pharmacopoeia, to final inspection.

Inventory control, expiration date control, and class control of raw materials and pharmaceutical products are performed through barcode checking for early detection of dispensing errors and missing products.

Data can also be linked to order placement processing.

This reduces the administrative workload such as checking the content of tests prescribed by the Japanese Pharmacopoeia and printing the necessary documents, and improves work efficiency.

This is a system that packages inspection of various processes and inventory control, a first in the industry.

Its compact design allows it to be installed in a variety of locations, including preparation rooms and clean rooms.

The high versatility of the system, with barcode authentication and management, and various scales that can be used for different types of products, adds to the appeal of this system.

You can see FAQ for our machines & equipments as well as movies about how to replace consumables and how to clean the machine.

Contact us by telephone

+81-3-3745-0790

[Overseas Business Division]