Site Search

One-dose packing requires that all pouches be visually checked.Such work places high demands on inspectors and always involves potential risks.

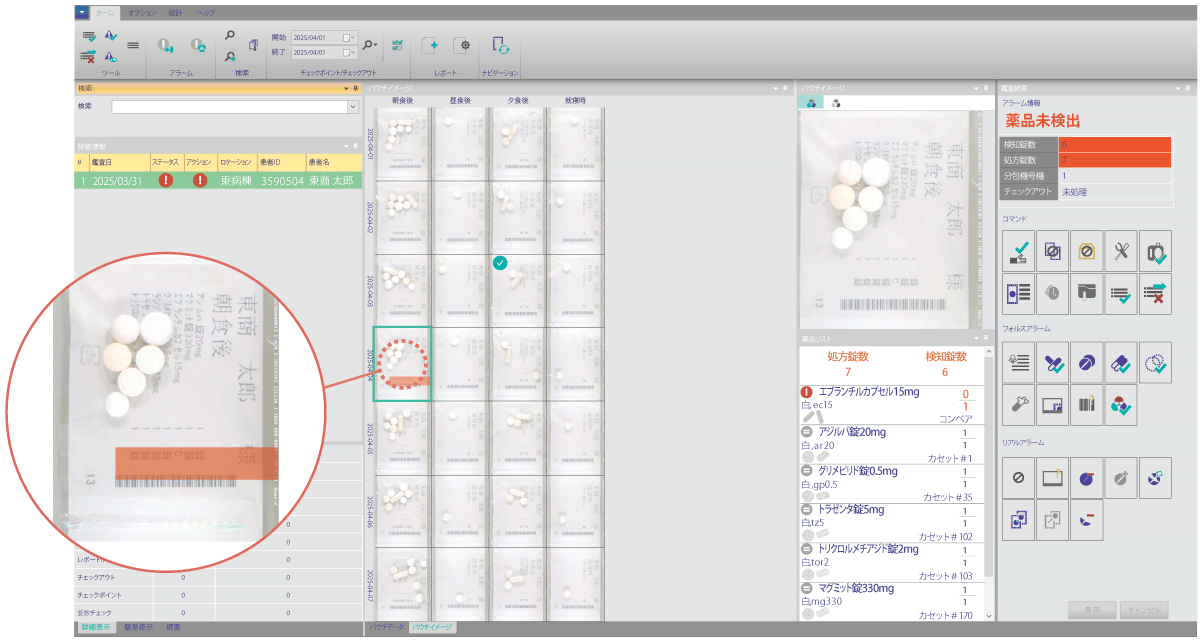

With the expanding use of tablet packing machines, more and more medicines are being distributed in single-dose packing.Dispensing inspection workloads have been increasing as a result, and there are cases of erroneous dispensing of non-prescribed drugs or dispensing of medicines in incorrect amounts.

Dispensing work and inspection work must be done in parallel.In that process, the inspection of one-dose packs is a simple task, but it is work that puts a heavy burden on inspectors.

Visual inspection does not guarantee accuracy in terms of work history verification and safe dispensing.

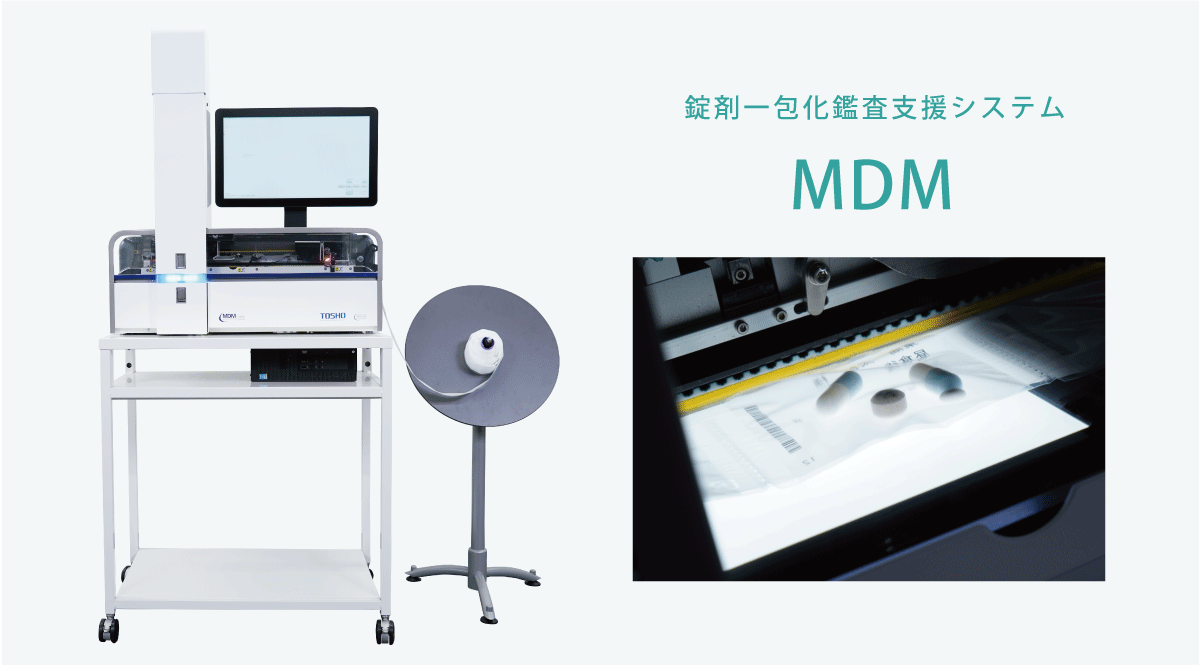

The inspection system linked with prescription data consistently supports one-dose packing inspection work.The system performs image analysis of one-dose medicines for a more scientific approach to inspections.By separating the work performed by humans from that performed by machines, it allows people to focus on checking areas that require verification.

Carrying out work with the help of a verification system reduces the need for visual inspection by humans and eases the burden on workers.

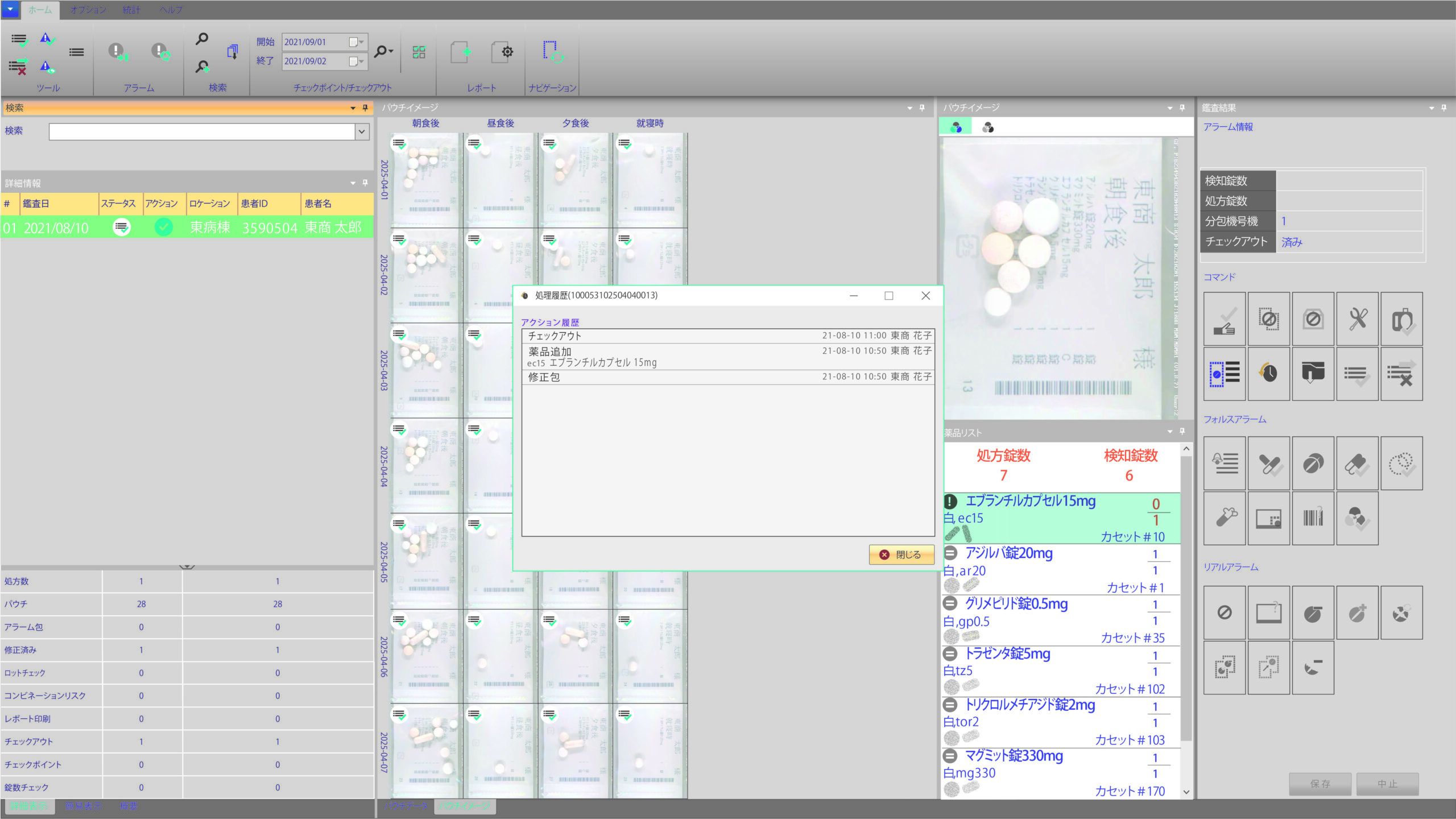

MDM-processed prescriptions are saved as images of all the pouches.When dealing with inquiries following the dispensing of medicines or when checking dispensing records, the user can refer to saved images of the medicines and a record of how any system-generated alarm regarding mistakenly dispensed medicines was dealt with.

This guarantees the quality of dispensing and the accurate delivery of medicines to patients.

We provide solutions that improve the inspection work environment so that pharmacists can spend more time on academic work.